Challenges faced by renewable diesel producers?

0

Related videos

September 10, 2020 | 00:54

Unlock the potential of your corn fiber - with Fiberex®

Traditionally, starch has been the only part of a corn kernel used in ethanol production. Until...

February 01, 2021 | 03:34

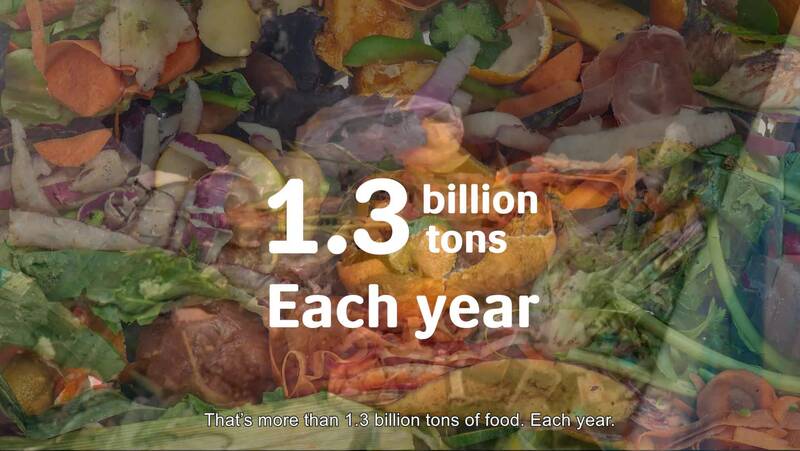

Biogas: Enzymatic pretreatment of food waste

Enzymes work as biocatalysts for biological processes, and can help the production of biogas...

May 03, 2023 | 04:35

2022 TECO – Latin America

Novozymes hosted TECO Latin America 2022 on August 8th 9th bringing together the most important...

October 19, 2023 | 05:16

TECO 2023

TECO 2023 was held in Sao Paulo, Brazil. Novozymes was honored to host the leading corn ethanol...